Earlier this year, I was thrilled to receive my new 36” x 54” tabletop monotype press from Michigan’s Conrad Machine Co. It came, via a freight carrier, disassembled and carefully packed in two crates. The press and workbench were packed together and there was a separate, flat crated press bed. In total, they weighed a little more than 600 lbs.

Conrad Monotype Press with Stand

The first, and most urgent challenge was uncrating the components and moving them into the studio before it rained. I could only have done it with the help of my amazing wife. Some of the reasons I chose this particular press over a traditional etching press is that it weighs less and can be moved through a standard-width door in pieces.

The delivery of my crated Conrad Monotype Press. There was a separate flat press bed crate, too (not in the picture).

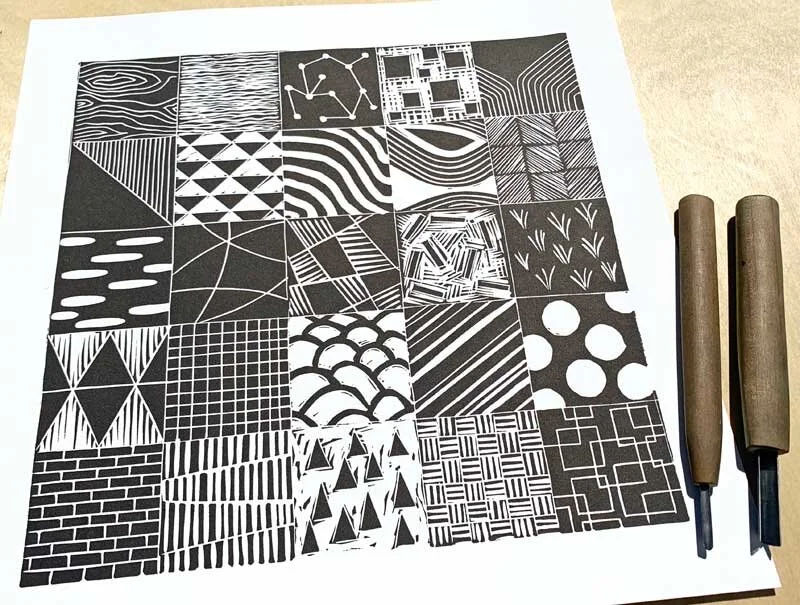

Over the coming days, I put together the steel stand, which has hefty casters, and mounted the press to the 3/4” plywood bench top that I had custom cut at a local lumber shop. I decided to paint the top with a multi-color geometric design. This is how it turned out, all set up.

Overall, I’m impressed by the quality of the press. When I ordered it over the phone with Conrad, it was nice to be able to ask questions and customize the press how I wanted. If you’re ever ordering one of these, keep in mind that it can take many months to fulfill an order based on my experience. I’ve only used it a little since I got it but I’m really excited to print some big linocuts.